We know that the injection mold consists of a movable mold and a fixed mold. The movable mold is installed on the moving template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form a gating system and a cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic product. So how much do you know about the use of this product? The following is a brief introduction to the precautions before the injection mold is tried.

The precautions before the injection mold trial are detailed as follows:

1. Understand the knowledge about injection mold: It is recommended to obtain the design drawing of the injection mold, analyze it in detail, and then let the injection mold engineer participate in the test work.

2. First check the mechanical cooperation on the workbench: pay attention to whether there are scratches, missing and loose parts, whether the sliding action of the mold is real, and the water pipe

and air fittings for leaks, and if the injection mold opening is a limitation, should be marked. If the above actions can be done before hanging the injection mold, the problems found when hanging the injection mold can be avoided, and then the wasted man-hours when removing the injection mold can be avoided.

3. When it is determined that the movement of each part of the injection mold is completed, it is necessary to select a suitable injection molding machine.

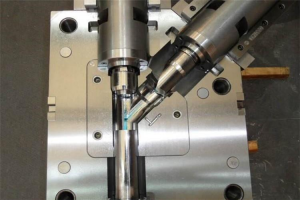

4. When hanging the mold, it should be noted that before locking all the splints and opening the mold, do not remove the lock and prevent it from falling off due to loose or broken clamps. After the mold is installed, the mechanical action of each part of the mold should be carefully checked, such as whether the sliding plate and thimble are functioning correctly and whether the nozzle is aligned with the feeding port.

5. When closing the mold, the clamping pressure should be reduced. During manual and low-speed clamping operations, attention should be paid to observe and listen for any movements and abnormal sounds. The process of lifting the mold is actually quite simple. The main thing to note is that the mold gate and nozzle center are more difficult. Usually, the center can be adjusted with a test strip.

6. Select a suitable mold temperature control machine to increase the mold temperature to the desired temperature during the production process. After the mold temperature has increased, check the movement of each part again. Since steel can cause die-cutting due to thermal expansion, care must be taken for each part to slip to prevent chattering.

Post time: Jan-20-2022